Misją Instytutu jest dzialalność naukowo-badawcza prowadząca do nowych rozwiązań technicznych i organizacyjnych użytecznych w kształtowaniu warunków pracy zgodnych z zasadami bezpieczeństwa pracy i ergonomii oraz ustalanie podstaw naukowych do właściwego ukierunkowywania polityki społeczno-ekonomicznej państwa w tym zakresie.

PREVENTION OF THREATS OF ULTRASONIC NOISE

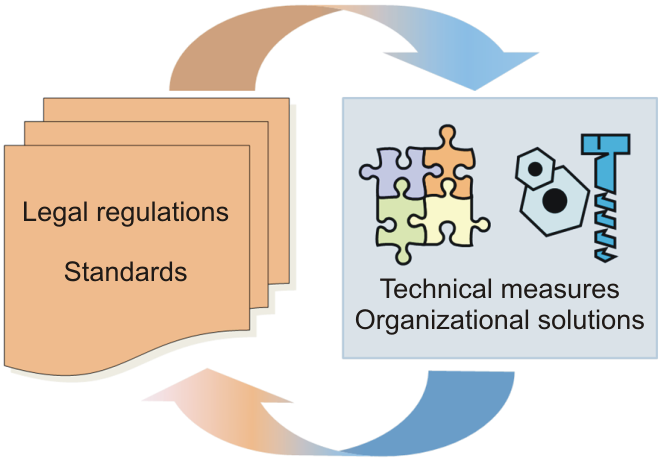

The prevention of ultrasonic noise hazards basically coincides with the noise hazard prevention. Activities aimed at limiting exposure to ultrasonic noise and the associated occupational risk should include technical and / or organizational solutions that can be implemented in a given situation, meeting the requirements of legal regulations and standards (Fig. 1).

The prevention of ultrasonic noise hazards basically coincides with the noise hazard prevention. Activities aimed at limiting exposure to ultrasonic noise and the associated occupational risk should include technical and / or organizational solutions that can be implemented in a given situation, meeting the requirements of legal regulations and standards (Fig. 1).

Fig. 1. The link between legal solutions and technical and organizational methods of combating ultrasonic noise.

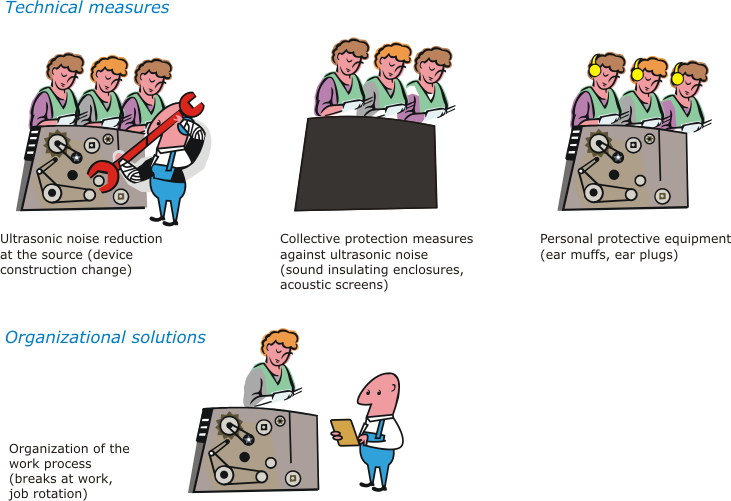

Measures to reduce the risk of ultrasonic noise should be applied according to the following

diagram (Fig. 2):

- Elimination of the risk by reducing it at the source of its origin,

- The use of collective protection measures against ultrasonic noise (limiting ultrasonic noise through transmission),

- Use of personal protective equipment,

- Introduction of organizational solutions.

Fig. 2. Limiting the risks of ultrasonic noise.

Eliminating the risk by reducing it at its source is a technical solution that brings the best results, but not always feasible for technical or economic reasons. The basic measures to reduce ultrasonic noise at its source include:

- using the quietest technological processes,

- using the quietest possible means of production (both the type and the unit),

- reducing the emission of ultrasonic noise from sources.

The reduction of the emission of ultrasonic noise is significantly influenced by the proper use of the machine in accordance with its intended purpose, the use of acoustic protection elements of the machine attached to the machine by the manufacturer, proper maintenance of the machine and keeping it in good technical condition.

If it is not possible to reduce ultrasonic noise at the source of its generation, appropriate technical and organizational measures should be applied to limit ultrasonic noise along the path of its propagation (transmission), ultrasonic noise reaching humans (reduction of immission) or to limit exposure to ultrasonic noise.

Collective protection measures against ultrasonic noise make it possible to reduce this noise in the way of transmission. Due to the specificity of ultrasonic noise and its sources (exposure mainly near the noise source due to the strong suppression of ultrasonic noise in the air, strong directivity of ultrasonic noise sources), the most effective measures to reduce ultrasonic noise along the path of its propagation are soundproofing and insulating housings, acoustic screens and acoustic silencers.

Sound-absorbing and insulating (sound-insulating) casings are used to completely isolate a noisy machine from the rest of the working environment or to shield the most noisy machine parts. The sound-absorbing and insulating properties of materials and casings made of them in the frequency range of ultrasonic noise are the subject of the latest research.

Personal protective equipment against ultrasonic noise should be used only when it is not possible to eliminate the risk related to ultrasonic noise by using other solutions. These measures include hearing protectors and head protection (helmets or helmets with transparent screens made of e.g. acrylic glass (plexiglass)), which should be used especially when the employee is close to the source of ultrasonic noise.

Hearing protectors for ultrasonic noise are noise hearing protectors (there is no separate category for ultrasonic noise hearing protectors). The hearing protectors used should be CE marked (which means that they meet the requirements of the directive (regulation) on personal protective equipment) and selected in terms of acoustic parameters for noise at the workplace, as well as in terms of individual characteristics and needs of the employee. It should be remembered that the selected protectors must properly cooperate with other personal protections used, such as, for example, helmets or glasses. The essential element in the selection of hearing protectors is to estimate the expected sound pressure level of the noise under the protector, taking into account both the attenuation parameters of the protector and the noise parameters. Standardized methods for selecting hearing protectors mainly relate to the range of audible noise. For this reason, when selecting hearing protectors, one should follow not only the requirements of the PN-EN 458: 2016 standard, but also other recommendations and methods resulting from the latest research [Młyński R., Kozłowski E., Stosowanie indywidualnych ochron słuchu w przypadku hałasu o częstotliwościach słyszalnych powyżej 8 kHz (The use of individual hearing protectors in the event of noise with audible frequencies above 8 kHz)]. In the case of ultrasonic noise, hearing protectors with high attenuation in the field of high-frequency noise (high H parameter of the protector) are preferred.

The organizational solutions enabling the limitation of exposure to ultrasonic noise include:

- taking breaks at work and limiting the time of work in noisy workplaces,

- job rotation,

- separation of areas where works with low ultrasonic noise emission are performed from areas where works with high ultrasonic noise emission are performedo,

- grouping of sound sources depending on the sound pressure level of the emitted ultrasonic noise,

- moving people away from noisy processes (robotization and automation),

- appropriate location of the sources of ultrasonic noise in relation to each other and in relation to the walls of the room.

By grouping sources of ultrasonic noise in different rooms and by separating work areas with different levels of ultrasonic noise emission, employees operating a quieter device (located in one room) are not exposed to ultrasonic noise from louder devices (located in another room). As a result, the number of employees exposed to ultrasonic noise is limited.

MEDICAL PREVENTION

An important supplement to technical and organizational activities aimed at minimizing the risk related to the occurrence of ultrasonic noise in the work environment is medical prophylaxis. Pursuant to Art. 229 of the Labour Code, employees are subject to initial, control and periodic medical examinations.

The employer may not allow an employee to work without a valid medical certificate stating that there are no contraindications to work in a specific position. These tests are carried out, if possible, during working hours and their costs are covered by the employer. The scope of initial, periodic and control medical examinations, the frequency of periodic examinations and the scope of preventive health care for employees was specified in the regulation of the Minister of Health and Social Welfare of May 30, 1996 on medical examinations of employees, the scope of preventive health care for employees and medical certificates. issued for the purposes provided for in the Labour Code (Journal of Laws Dz.U. 1996, No. 69, item 332, consolidated text of Journal of Laws Dz.U. of 2016, item 2067).

Preventive examinations are carried out on the basis of a referral issued by the employer, which should specify the type of preventive examination, the position at which the employee is or is to be employed and information about the presence of harmful or nuisance factors at this position (along with measurement data).

The scope and frequency of preventive examinations are specified in the annex to the above-mentioned regulation. For ultrasonic noise, the tests include:

An important supplement to technical and organizational activities aimed at minimizing the risk related to the occurrence of ultrasonic noise in the work environment is medical prophylaxis. Pursuant to Art. 229 of the Labour Code, employees are subject to initial, control and periodic medical examinations.

The employer may not allow an employee to work without a valid medical certificate stating that there are no contraindications to work in a specific position. These tests are carried out, if possible, during working hours and their costs are covered by the employer. The scope of initial, periodic and control medical examinations, the frequency of periodic examinations and the scope of preventive health care for employees was specified in the regulation of the Minister of Health and Social Welfare of May 30, 1996 on medical examinations of employees, the scope of preventive health care for employees and medical certificates. issued for the purposes provided for in the Labour Code (Journal of Laws Dz.U. 1996, No. 69, item 332, consolidated text of Journal of Laws Dz.U. of 2016, item 2067).

Preventive examinations are carried out on the basis of a referral issued by the employer, which should specify the type of preventive examination, the position at which the employee is or is to be employed and information about the presence of harmful or nuisance factors at this position (along with measurement data).

The scope and frequency of preventive examinations are specified in the annex to the above-mentioned regulation. For ultrasonic noise, the tests include:

- Initial examinations:

- medical examinations - general and otolaryngological,

- auxiliary tests - tonal audiometric tests in the range of 125-8000 Hz (air and bone conduction),

- Periodic tests:

- medical examinations - general and depending on the indications - otolaryngological,

- auxiliary tests - tonal audiometric tests in the range of 125-8000 Hz (air and bone conduction),

- Recent periodic examinations:

- for medical examinations - general and otolaryngological,

- auxiliary tests - tonal audiometric tests in the range of 125-8000 Hz (air and bone conduction).

Periodic examinations should be performed every 2 years.

The doctor who conducts preventive examinations may extend the scope of examinations with additional specialist consultation examinations and additional examinations, as well as appoint a shorter period for the next examination, if he decides that it is necessary for the proper assessment of the health condition of the person hired for work or the employee.

Medical examinations are aimed at eliminating people whose health condition differs from normal when working with ultrasonic noise, as it may deteriorate further as a result of exposure to ultrasonic noise. These tests are also aimed at capturing the early symptoms of pathological changes (hearing damage) resulting from exposure to ultrasound noise and preventing the disease from getting worse.